You are here: home > What is MCOB/COB LED Packaging > What is MCOB/COB LED Packaging

Product (206)

- LED PL Light (10)

- LED Spot Lights (28)

- LED Flexible Strip (10)

- LED Tube Lights (22)

- LED Floodlight (48)

- LED Lights Bulbs (33)

- LED Recessed Lights (12)

- LED Downlights (24)

- led Solar Light (2)

- LED PAR Lights (4)

- LED Ceiling lights (8)

- LED Street Lights (5)

Blog (2)

Certificates (2)

After-Sales Service Policy (1)

MCOB---the new generation of LED lighting (1)

What is MCOB/COB LED Packaging (1)

Sample Policy (1)

Payment Terms (1)

Sywell Lighting--Your Best Option (1)

Credit Report

Products Index

Company Info

Sywell Industrial Co., Ltd. [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

What is MCOB/COB LED Packaging

What is MCOB/COB LED Packaging

LED COB package---

LED lighting is a new generation, with energy saving features, but not perfect. Compared with conventional light sources, because of its high luminous intensity per unit area, so a serious glare. When you need a large wattage light source, you need to install more LED stars together, not to mist or haze filter lens case, there will be serious zebra pattern, the use of fog or mist filter lens, the light will bring no small loss.

LED lighting is a new generation, with energy saving features, but not perfect. Compared with conventional light sources, because of its high luminous intensity per unit area, so a serious glare. When you need a large wattage light source, you need to install more LED stars together, not to mist or haze filter lens case, there will be serious zebra pattern, the use of fog or mist filter lens, the light will bring no small loss.

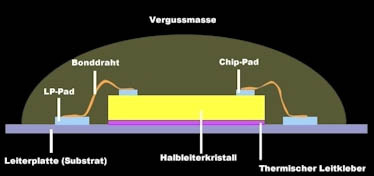

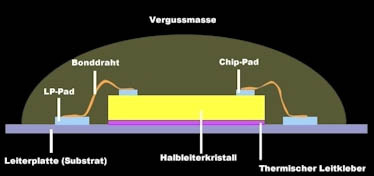

The core technology uses LED cluster package COB (Chips On Board), makes light-emitting area is increased several times, increasing the power of a single source package, the maximum resolution of the LED light source of the glare problem, the problem zebra and increased efficiency and reduced light resistance, reduce manufacturing costs.

LED MCOB package and the difference between LED COB packages---

Now the COB LED package, including the COB packaging technology in Japan, are based on the package substrate. the substrate is in the succession of the N-chips integrated with the package. We all know below the substrate is copper foil. Copper foil can only be good at power conduction, cannot do a very good optical processing.

MCOB is different from traditional package. MCOB package, is put the chip into optical cups directly, not only one cup, but several cups. Based on the optics theory, LED chip just concentrate inside the chip. To make light running out more, need a lot of angles. MCOB package, the efficiency of low-power package must be greater than the high-power package. The high-power chip only has 4 sides light exits. MCOB use small chip into 16 pieces. So the emitting area is 4 x 16 times of the high power chip.

It is No doubt that increase the light exits as many as possible, then efficiency can increase. Meantime, the thermal resistance will be reduced with the cooling area coming large.

MCOB package technology breaks through the traditional packaging technology to solve the COB LED light efficiency is low, the problem of slow cooling, while also reducing costs.